Thermal Imaging

Thermal Imaging For Boat Hull, Structure and Machinery

What is Thermal Imaging and how do we apply it to our surveys ?

Thermal imaging also referred to as infrared thermography is the observation and recording of the temperature variations of an object which are not visible to the eye. Thermal imaging cameras capture the radiation emitted from an object within the long-range infrared wavelength, converting the data into images called thermograms. Positioned between visible light and microwaves on the electromagnetic spectrum the main source of infrared radiation is thermal radiation or heat, any objects having a temperature above -217.15 degrees celsius or absolute zero will emit radiation within the infrared spectrum.

That’s all well and good but what does is all really mean in a boat survey?

If we consider the hull, fittings, decks and structure. Water damage, water retention, delamination, cracks and fractures will return cooler temperatures with irregular patterns in and around the areas of concern. Patch repairs and inserts in fibreglass, steel and aluminium may have been completed to a very high standard and not be visible under paint topcoats or gelcoats, they will however still be detectable with the use of the thermal imaging camera. With the differing levels of radiation emitted by various components of the boat structure and internal fittings we can locate supporting frames, stringers, structures, water and fuel tanks in contact with or very close to the hull. With thermal radiation we can utilise the other end of the spectrum with higher temperatures to highlight potential machinery component failures common to engines, exhaust systems, turbos, bearings, battery and solar panel cells which are overheating.

What does this mean for a boat owner or the perspective buyer?

One of the biggest advantages of thermal imaging other than seeing what the naked eye cannot, is that the whole process is completely non invasive, there is no dismantling, taking part or risk of damage being caused to the boat or any components during the inspection. Above all with a full thermal survey boat owners and buyers obtain a very clear idea with images as to the complete condition of the boat reducing the unknown factor of what cannot be seen, while also providing a full scope of works required for ongoing and preventive maintenance or repairs and being time and cost efficient. While technology allows us to locate issues without employing destructive methods it can also show the boat does not have abnormalities giving a greater confidence in the condition of the hull, deck, structure and machinery.

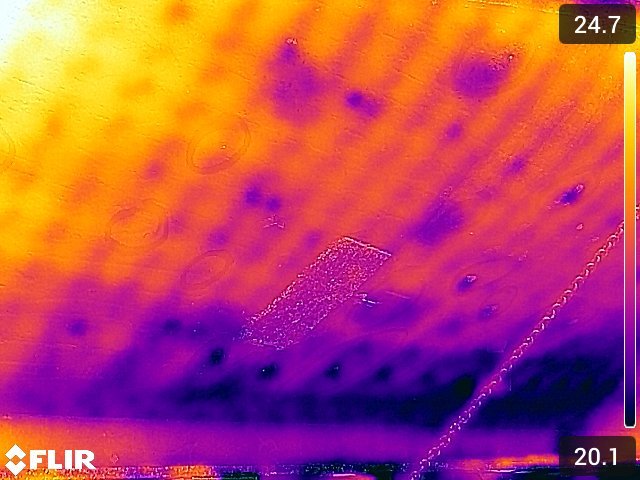

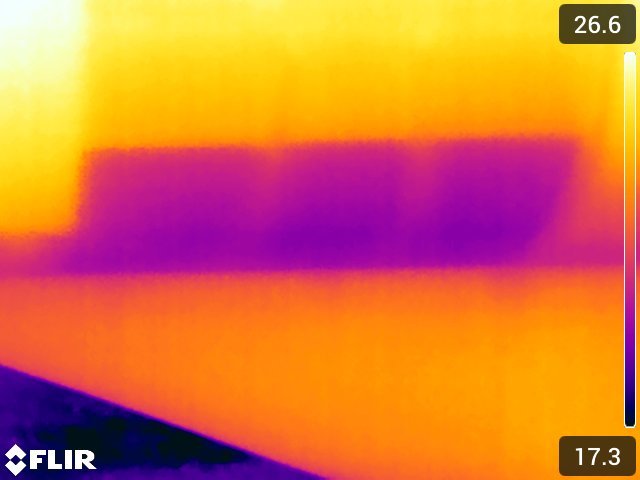

Below are examples of water damage and patch repairs to the hulls of boats along with tank locations using thermal and picture in picture images the water damage is spread throughout the length of hull emanating in and around the hull fastenings.

Hull water damage

Patch repair not visible beneath the antifoul

Location of the fuel tank

Allowing the hull and structures time to absorb radiant heat will increase the range of infrared radiation emitted from the boat, this increase in temperature difference provides us with a greater definition of the image for analysing highlighting areas of potential water damage, delamantion or repairs. As the thermal imaging equipment is not dependent on daylight to capture images we can also artificially heat the boat with incandescent work lights when working in refit bays and shipyard facilities. As each is day and location is different with variations in the prevailing weather conditions the equipment is fined tuned further to ensure the best possible results are achieved with additional inputs for the ambient air temperature, relative humidity and reflected heat all applied to the thermal camera to gain true infrared radiation readings. With the advancement in technology the applications of the thermal imaging camera lends itself to being able to provide comprehensive condition and assessments of all of the major components of a boat.

Typical infrared thermal applications in a boat survey;

Hull and structure of steel, aluminium, wood and fibreglass boats

Moisture retention and damage

Delamination and disbonding of fibreglass

Repairs underneath topcoats of paint and gelcoat

Engine component, turbo, exhaust and bearing overheating

Solar panel efficiency and defective cell identification

Battery cell damage and overheating

Air condition efficiency and leak location

Thermal imaging can be included in any of our surveys or as a stand alone service.

Tank identification

Patches around overboard discharges and on a rudder

Delamination in a GRP hull

Rudders and propellers return returning consistent temperatures with images free from abnormalities

We use the FLIR hardware in conjunction with the FLIR supporting software. FLIR’s cameras provide digital, thermal, thermal MSX (thermal image with a digital overlay) and picture in picture imagery.